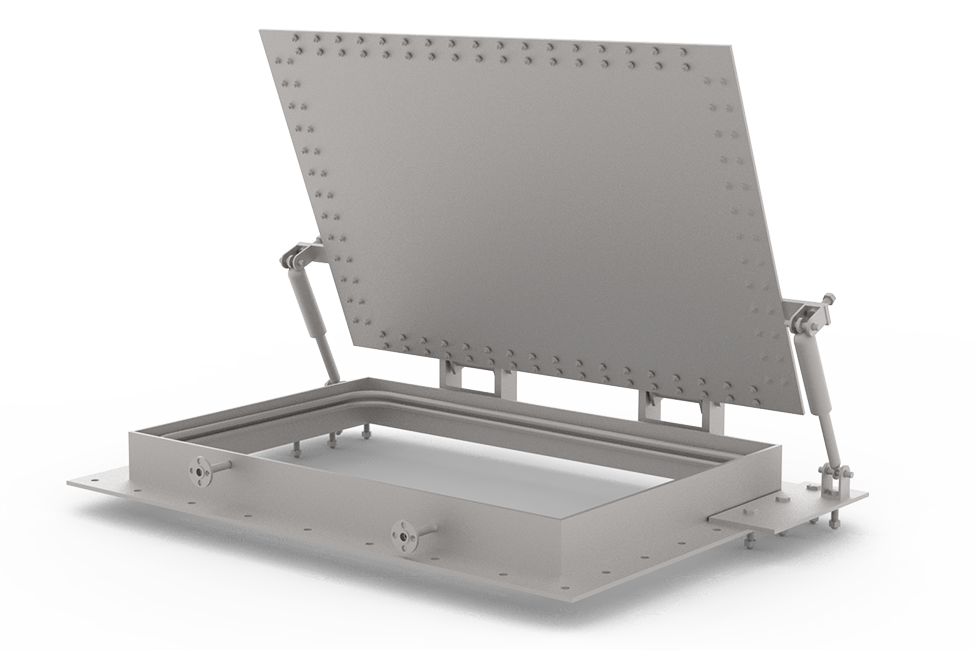

**Explosion hatches**, also known as “explosion relief vents”, are designed to protect enclosed spaces from sudden pressure surges caused by explosions or deflagrations. They provide a controlled release of excess pressure to prevent structural damage and ensure safety.

- **Instantaneous Pressure Relief**: Opens rapidly when internal pressure exceeds safe limits.

- **Low Set Pressure**: Typically designed for **low-pressure relief** applications.

- **Leak-Tight Design**: Prevents unintended emissions while ensuring proper venting.

- **Material Durability**: Often made from **aluminum, stainless steel, or reinforced composites** to withstand harsh conditions.

Explosion hatches are widely used in industries where combustible dust, gases, or vapors pose a risk:

- **Chemical Processing Plants**

- **Petroleum & Gas Storage Facilities**

- **Food Processing (grain milling, sugar refining)**

- **Pharmaceutical Manufacturing**

- **Mining & Energy Facilities**

- **Battery Storage & Hydrogen Applications**

Explosion hatches must comply with various safety standards to ensure effectiveness:

- **NFPA 68** – Standard for explosion protection by deflagration venting.

- **EN 14491** – European standard for explosion venting in dust-handling systems.

- **VDI 3673** – German guideline for explosion protection.

- **FM Global 1-44** – Venting class for explosion mitigation.

| Feature | Explosion Hatches | API 520 Safety Valves |

| Purpose | Explosion relief | Overpressure relief |

| Opening Mechanism | Instantaneous | Gradual |

| Set Pressure | Low-pressure | Medium to high-pressure |

| Common Applications | Dust collectors, silos | Process piping, pressure vessels |

| Standards | NFPA 68, EN 14491 | API 520, API 526, ASME VIII |