**Rotary control valves** are widely used in industrial applications for precise flow regulation. Unlike sliding-stem valves, they operate with a **rotational motion**, where the valve disc or ball rotates to control fluid flow.

Rotational Motion: The valve element rotates to modulate flow.

- **Ball Valves**: Provide tight shutoff and high flow capacity.

- **Butterfly Valves**: Lightweight and cost-effective for large flow applications.

- **Plug Valves**: Used for throttling and isolation.

- **Manual** (lever or handwheel)

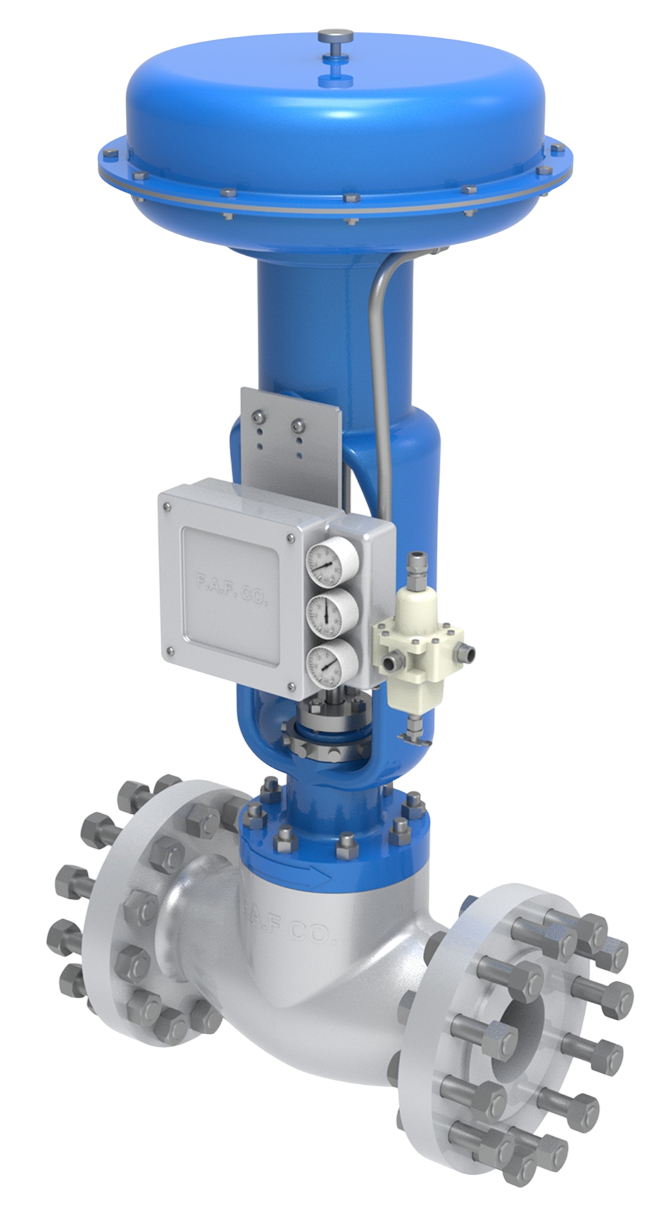

- **Pneumatic** (air-driven actuator)

- **Electric** (motorized control)

- **Materials**: Typically made from stainless steel, carbon steel, or special alloys for durability.

- **Flow Characteristics**: Designed for **high-capacity flow control** with minimal pressure drop.

- **IEC 60534-3-2**: Defines face-to-face dimensions for rotary valves.

- **IEC 60534-4**: Specifies seat leakage requirements.

- **IEC 60534-8.3 & 8.4**: Covers noise considerations in control valves.

- **API 598**: Establishes testing requirements for valve integrity.

- **ASME B16.34**: Governs pressure-temperature ratings for valves.

________________________________________________________________________________________________________________________________________